How Covid-19 Has Affected The Global Supply Chain

During the start of the pandemic in early 2020, the demand for goods and services plummeted as many countries around the globe went into lockdown. Manufacturing sites were cut in capacity, shipping vessels cancelled, and employees were laid off as Covid cases skyrocketed.

Closures of factories in China have resulted in a shortage of several goods and shipping container shortages have significantly increased rates for global shipping routes. Moreover, transportation labor shortages have resulted in significant delays in receiving goods. With high-demand for tradable goods, the system just can’t keep up with the Covid supply chain disruptions.

After the steep drop in global trade at the start of 2020 as the economy collapsed, the heightened demand during late 2020 and throughout 2021 caused massive breaks in the system from labor shortages to logistical complications. The intricate network that was once efficient at moving materials around the world, broke. This system requires punctuality and meticulousness in order to function effectively, and due to Covid-19, both were lost.

Some experts believe that as Covid-19 cases begin to shrink the workforce capacity, constraints should ease, relieving pressure off the system. Others state the contrary. From new waves of Covid-19 infections, to unforeseen extreme weather conditions, businesses may experience supply chain disruptions for far longer than anticipated.

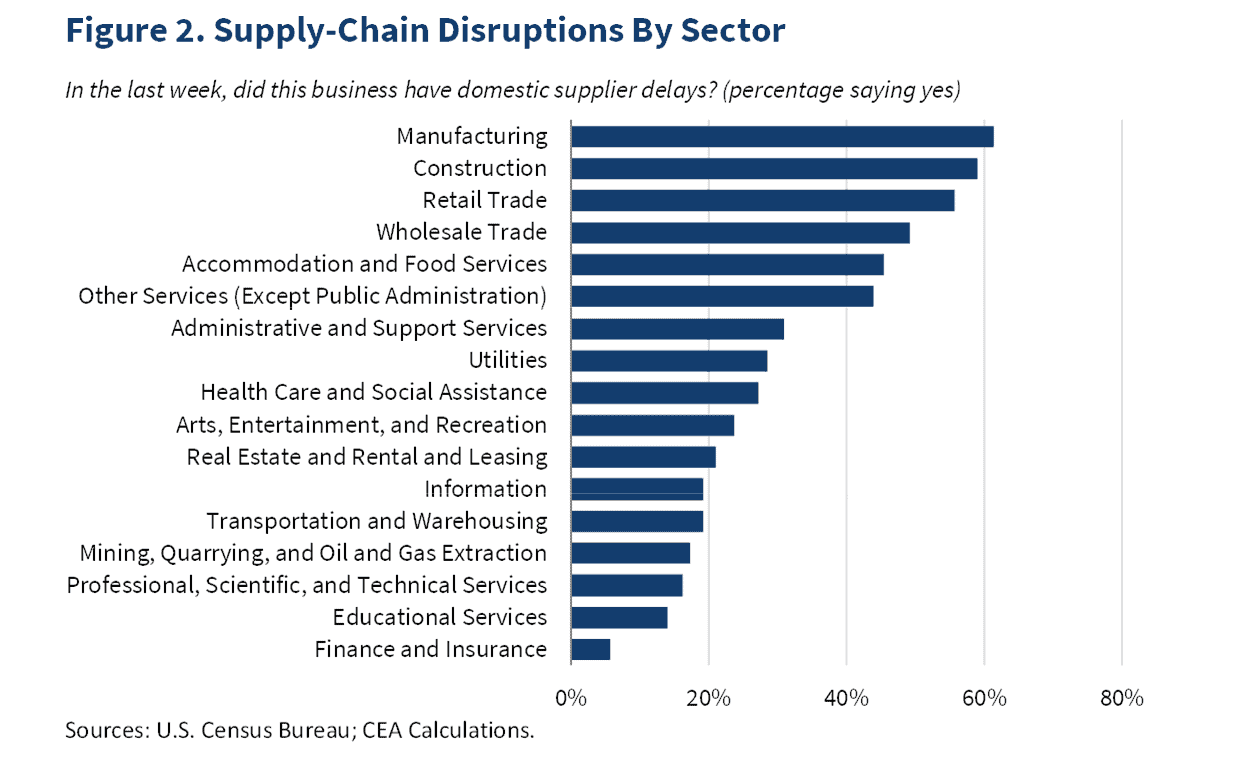

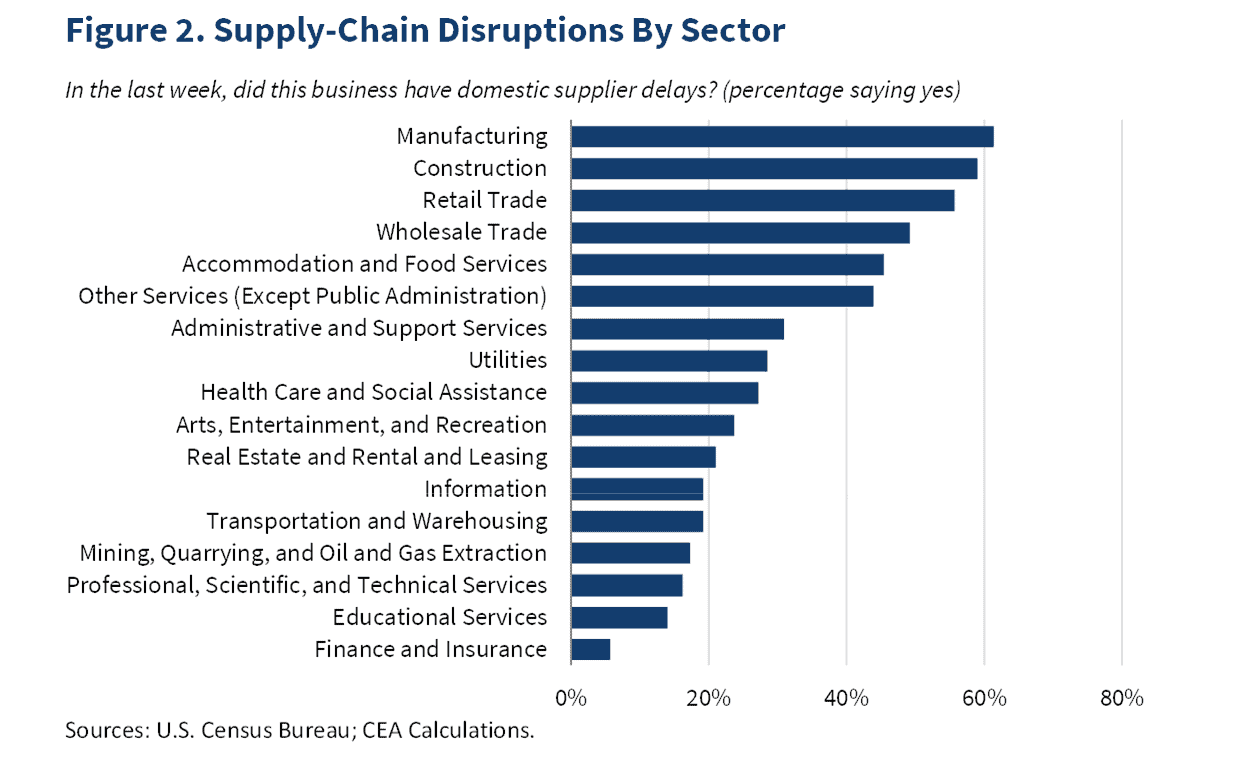

Certain industries have been impacted far more critically than others. Depending on factors like the availability of intermediate goods as well as the logistics of transporting and producing the goods.

The 2021 Small Business census conducted in early June, discovered that 36% of small businesses experienced delays with domestic suppliers.The manufacturing sector was impacted the greatest with over 60% of manufacturing businesses stating they have experienced domestic supplier delays in the past week.

The Effects of Supply Chain Disruptions On Businesses

Prior to Covid-19, businesses often spent the most money on employee payroll and marketing. Now, the burden of supply chain operations are quickly becoming their greatest expenses. The Producer Price Index revealed that in the year leading up to May 2021, commodity prices increased by 19%, the biggest increase since 1974. As of January 2022, this index is now up to 22%.

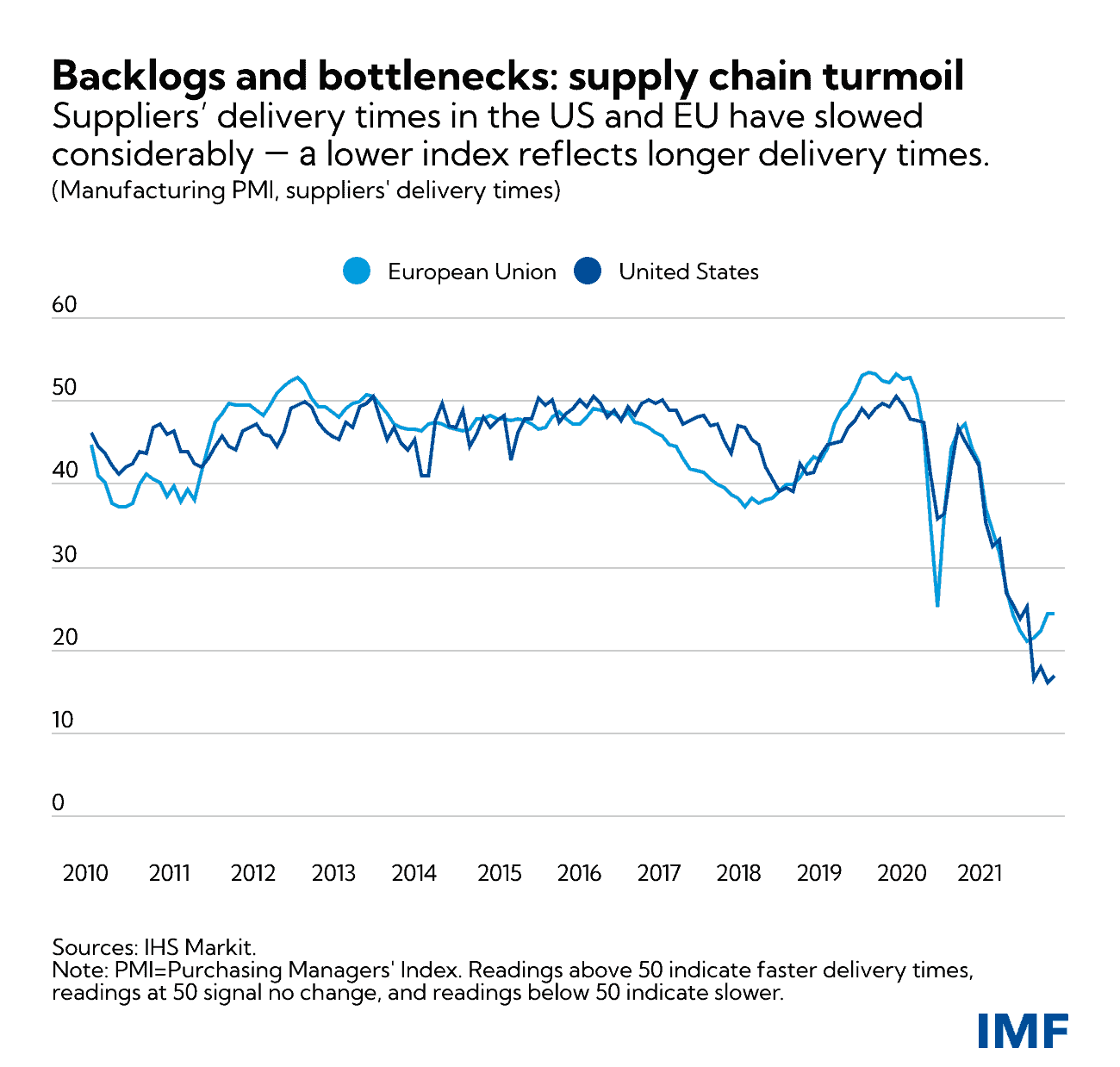

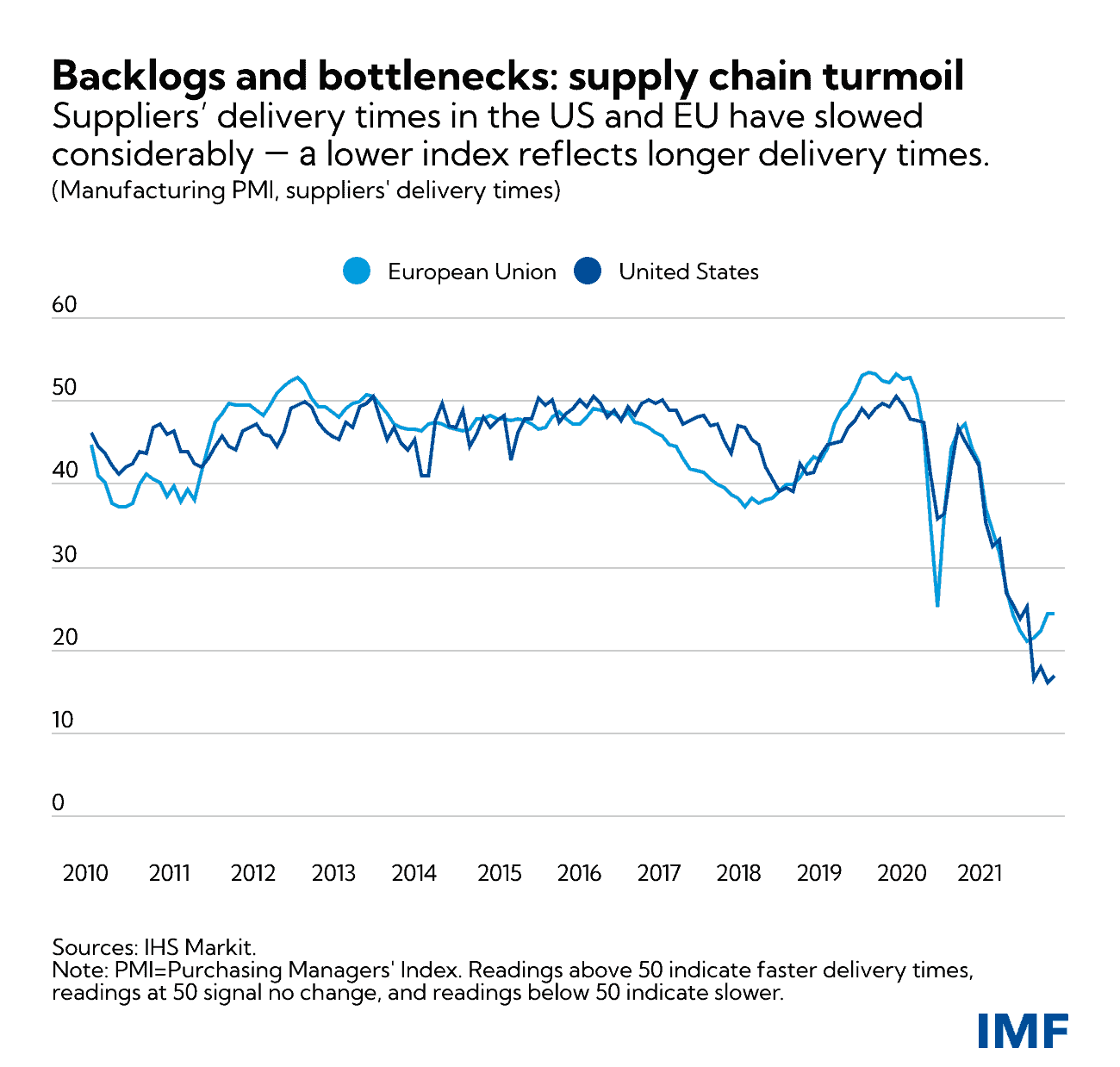

The IHS Suppliers Delivery Times Index further reflects the extent of the supply chain disruption. To calculate this index, purchasing managers were asked if their suppliers deliveries have been slower, faster, or unchanged on average compared to the previous month. Readings of 50 indicate no change, readings below 50 indicated slower delivery times, and readings above 50 indicated faster delivery times on average. In 2021, this index dropped below 20.

This acute drop seen in the Delivery Times Index reflects extreme demand, supply constraints, or a combination of the two. As a result, suppliers have more control over pricing, causing the sharp increase in the overall cost for goods.

Longer Delivery Times Reflect Supply Chain Disruptions

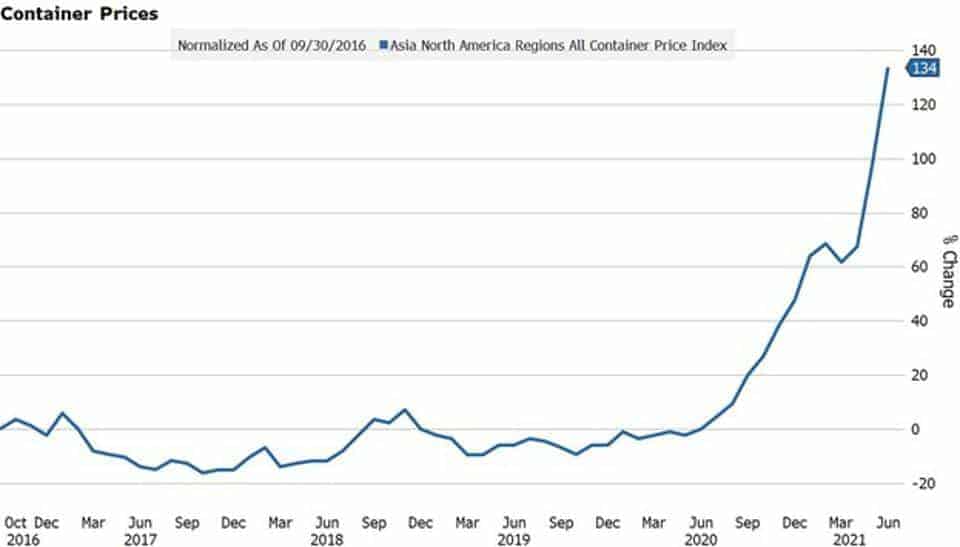

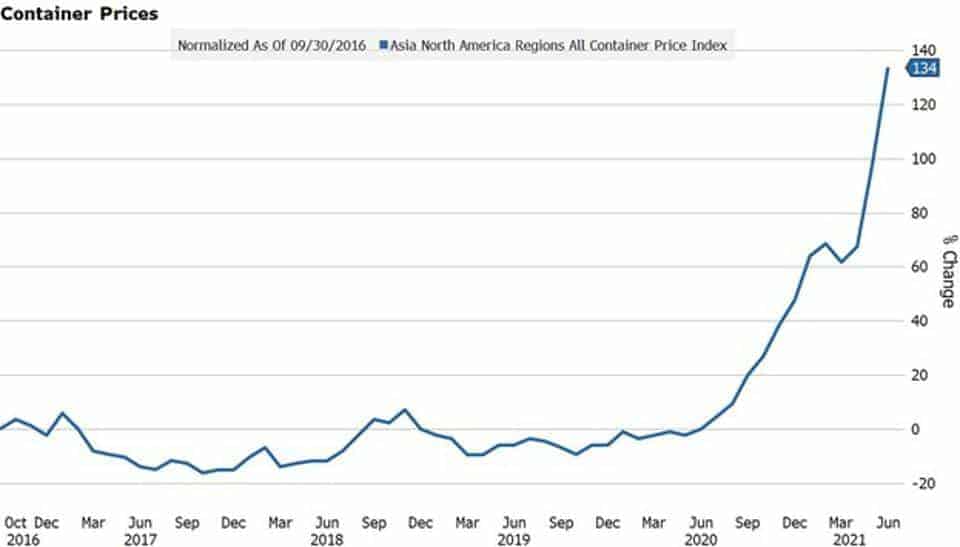

Beyond the imbalance of supply and demand, one of the other main elements negatively impacting the supply chain is the inability to effectively transport goods. For those attempting to transport goods globally, the costs are astronomical. Caused by a sharp increase in demand, the average cost for a 40 foot Chinese-manufactured cargo container is eerily close to $6000 USD which is more than double the cost from 2016.

The lack of container turnover is caused by several issues. There are an insufficient number of workers at ports to alleviate the congestion, leading to limited warehouse space.

The port of Los Angeles receives 17% of the U.S. national shipments, making it the busiest American port. Import volumes increased 27% from June 2020 to June 2021. However, the proportion of empty containers being shipped back to Asia due to demand jumped 47% in the past year. Exporters stated they cannot get shipping containers inland as distributors need to get them returned to Asia as promptly as possible. Until container circulation improves, the prices are likely going to continue rising, placing immense financial strain on businesses.

To help improve the circulation of shipping containers, more ships are required. Additional cargo vessels equating to approximately 20% of the world’s existing capacity are in production, although they will not be operational until 2023.

While additional shipping vessels appears to be a solution, this explanation comes with a whole list of complications. Cargo ships are much larger than they once were. Many are 2-3 times the size of vessels commonly seen in the early 2000s, and can carry 20,000 or more containers, which introduces additional infrastructure complications at the receiving ports.

Interestingly enough, productivity is 50% higher at the ports compared to pre-Covid, yet shipments are sitting 2.5 times longer on average. Again, this is all due to significant traffic at the ports.

The demand for warehouse space is at an all time high, as goods are unable to get moved fast enough. Trucking is one of the main transportation methods used to move cargo once they have been unloaded at the port. According to driver employment agencies, there is an extreme driver shortage with only one qualified truck driver per 9 job postings. Safety concerns, new unemployment benefits, and children learning from home are just a few reasons contributing to why drivers are leaving the industry. While salaries are increasing in the trucking industry, it may take more than a pay increase to convince drivers to return as many have moved onto occupations with better lifestyles.

Walmart is offering salaries more than double the median salary for the trucking industry to try and lure drivers in. While this helps out Walmarts logistics, it leaves smaller businesses left scrounging for workers and further obstructs movement at the ports.

Railroads are also experiencing similar battles. When the supply chain was working cohesively, trucks would transport shipments directly to railroad hubs then trains would move the cargo inland. Beyond the hiring difficulties partially due to disruptions caused by Covid-19, this enterprise faces other challenges. From extreme weather conditions to minor delays in shipment arrivals, the whole system can break down fairly easily.

From increased shipping container costs, shipping space, and insufficient warehouse storage space, businesses are having difficulty consistently getting goods to their customers on time. Leaders are spending more time and resources than ever, attempting to solve these troubles.

Supply Chain Disruption Examples

Since the beginning of the pandemic supply chain disruptions, there have been several enterprises with shared experiences. One of the recent supply chain disruptions is in the automotive industry.

Toyota announced in December 2021 that they will be ceasing manufacturing at 5 factories in Japan starting January 2022 due to semiconductor chip shortages caused by the global supply chain disruptions of 2021.

Apple is another company to join the list of brands experiencing difficulties because of semiconductor shortages. Apple announced late October 2021 that they are expecting lower than anticipated revenue for their 4th quarter due to supply chain disruptions. They predicted they will be capable of producing 90 million new iPhone 13 devices in their 4th quarter. However, due to these shortages it is expected they will reduce this goal by 10 million units, according to Bloomberg News.

The semiconductor chip shortage is just one of the many Covid supply chain disruption examples recently discussed in the news. Other intermediate goods shortages include lumber, rubber, and steel. These shortages, alongside the inability to move cargo, are the main reasons why businesses are working tirelessly to find new ways to regain control of their place in the supply chain.

How to Respond To The Supply Chain Disruptions of 2021

Covid-19 is not a type of risk event that companies could have prepared for. Due to the pandemic, radical changes have been observed in consumer behavior as well as logistics, complicating the workflow of companies. In order for the supply chain to operate cohesively, it is essential that each component of the chain works efficiently and effectively. However, each link in the chain has to conquer their own unique challenges, which has led to the extreme supply chain disruptions due to Covid.

A priority has been placed on leaders to quickly adapt new methods of operating within the supply chain, in order to stay afloat in this uncertainty. These new methods must encapsule repeated end-to-end assessment, short-term and long-term strategy development, and continuous monitoring of the situation.

When the pandemic started, leaders had to spend time on crucial, time-sensitive matters, such as raising capital and budgeting. When so much time was being spent on near-term matters, plans for the future fell behind. This is why experts in the industry recommend that leaders spend at least half of their time working toward the future of the company, because if their time is spent on other tasks, competitors may take their place. Many high-performing companies employ the use of third-party companies to manage their supply chain relations, as they are experts at maintaining relations with suppliers and ensuring products arrive on time.

Global Partner Solutions (GPSI) highlights that strategies cannot be executed overnight. Quality strategies involve continuous monitoring and modifications. Investing in supplier development will aid in aligning supplier and customer values and needs, reducing the risk of problems in the future. Further, this tactic will increase the likelihood of receiving a satisfactory product within a proper timeline, saving company time and resources.

Delivery Assurance is the reactive approach GPSI takes when shipments are expected or confirmed to be delayed. This is an essential strategy for companies to adopt as it will aid in getting them back on track. Both of these tactics are highly recommended for maintaining an efficient supply chain strategy.

When these tactics are outsourced to a third-party supply chain management partner, these strategies are often cost and time efficient. This is because having a well thought out strategy can reduce the need for reactive measures in a time of crisis.

With the utilization of a supply chain service partner, businesses are able to:

- Develop a supply chain strategy;

- Reshape their supply chain from customer forecast to inventory; and

- Accomplish a high performing supply chain strategy with excellent management that will last the test of time.

How Global Partner Solutions Can Help Resolve Your Supply Chain Concerns

GPSI has 15 years experience in uncovering how to quickly and effectively resolve both short-term and long-term supply chain concerns. GPSI’s Delivery Assurance and Supplier Recovery service is designed to mitigate supply chain complications. GPSI’s agents will learn the needs of the business, visit the suppliers location needing assistance, and work with the supplier to discover which processes can be optimized to accelerate critical orders and provide long-term improvements. These improvements will lead to permanent advancements in receiving on-time deliveries.

When a business reaches out in a time of need, GPSI applies their results-oriented approach to help companies cut delays and remove waste from their processes. When working with clients, GPSI begins with understanding the issues at hand. This includes learning the product specifications, manufacturing processes, and various issues that need optimization. Following this stage, GPSI will identify the skills and resources best suited to mitigate the problems faced, including the deployment of culturally-conscious experts to the suppliers location. Next, GPSI uncovers inefficient processes and hindrances at the suppliers site and an intervention plan is developed. This involves creating escalation processes, high level strategizing, and setting deadlines. Then the plan is executed, which may involve coaching the supplier’s team, realigning values and monitoring the existing strategy. At this point, an exit strategy is also underway that will allow for a permanent and sustainable improvement to the strategy. Finally, note the achievements attained. This includes evaluating customer satisfaction, added value, quality of the intervention, and any lessons learned.

GPSi Assists Business in Tracking 80,000 Parts For Medical Devices

At the beginning of Covid-19, a manufacturer was given a contract to produce 10,000 ventilators to aid those critically ill with the virus. This business utilized GPSI to lend a hand in managing the logistics of the components, accelerating product delivery times, and quality validation.

Over the course of the project, GPSI sent experts to the final assembly site as well as several sub-tier manufacturing sites in 4 different countries. During this time, GPSI tracked over 80,000 parts manufactured in 6 months. Additionally, GPSI monitored and reacted to any shortages or delays to ensure production lines were supplied on time.

It is recommended more than ever to employ experts in Supply Chain Management as the supply chain landscape has changed significantly and permanently since the beginning of Covid-19. Unforeseen events can occur at any time, it is best practice to utilize a third party to manage supplier development and delivery assurance to ensure your company is not negatively impacted by the supply chain disruptions going on today. Doing so allows precious company time to be reinvested into areas that need more attention, and working with experts in the industry will improve the synergy between the company and its suppliers long-term.