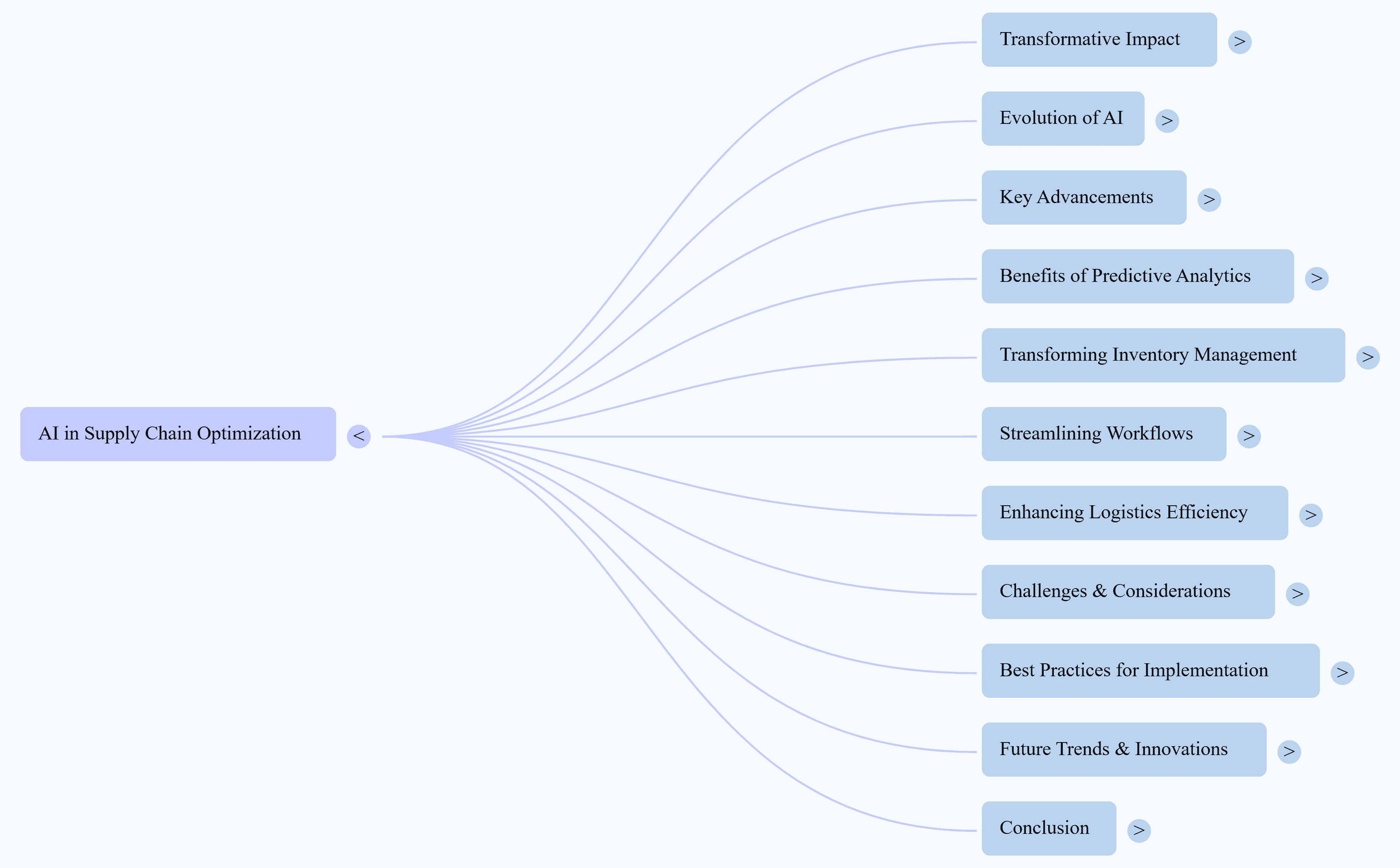

The Evolution of Artificial Intelligence in Supply Chain Management

Artificial Intelligence (AI) has transformed supply chain management and logistics operations over several decades. Research shows that the journey began in the 1950s with simple rule-based systems and has progressed to today’s sophisticated machine learning algorithms capable of handling complex, multi-variable optimizations.

AI and Supply Chain in the 1980s

Early AI applications in the supply chain focused on inventory management and demand forecasting. In the 1980s, companies started using expert systems to codify human knowledge for warehouse layout design and vehicle routing tasks.

AI and Supply Chain in the 1990s

The 1990s saw the rise of data mining and neural networks in supply chain analytics. Retailers like Walmart pioneered these technologies to analyze vast transaction data and improve demand forecasts. The 1990s also marked the beginning of automated planning and scheduling systems in manufacturing.

AI and Supply Chain in the 2000s

The 2000s brought significant advancements in machine learning and optimization algorithms. Companies began using these techniques for dynamic pricing, supply network design, and real-time logistics optimization. The advent of cloud computing and big data technologies in the 2010s further accelerated AI adoption in supply chains.

Today, AI is being applied across the entire supply chain, from procurement to last-mile delivery. Machine learning models can predict demand with unprecedented accuracy, while reinforcement learning algorithms optimize complex logistics networks in real time.

Advancements in AI-driven Supply Chain Optimization

Some advancements in supply chain optimization regarding AI are:

- Predictive Analytics for Demand Forecasting

- Autonomous Planning and Execution

- Intelligent Automation in Warehouses

- Supply Chain Visibility and Risk Management

- Personalized Customer Experience

Predictive Analytics for Demand Forecasting

Advanced machine learning models now incorporate various variables, including social media trends and weather data, to accurately forecast demand. So this has led to significant reductions in inventory costs and stockouts. According to a McKinsey study, AI-powered demand forecasting can reduce errors by 30-50% in supply chain networks.

Autonomous Planning and Execution

AI systems can now autonomously plan and execute supply chain operations, adjusting to disruptions and changing conditions in real-time. Remember, this includes everything from production scheduling to route optimization for delivery vehicles.

Intelligent Automation in Warehouses

The integration of AI with robotics has revolutionized warehouse operations. AI-powered robots can navigate warehouses, pick and pack items, and predict maintenance needs, dramatically improving efficiency. Amazon reports that its AI-driven robotics have cut operating expenses in fulfillment centers where they’ve been deployed.

Supply Chain Visibility and Risk Management

AI algorithms now process vast amounts of data from various sources to provide end-to-end visibility across the supply chain. These systems can predict potential disruptions and suggest mitigation strategies in real time.

Personalized Customer Experience

AI enables hyper-personalization in supply chain operations, allowing companies to tailor products and delivery options to individual customer preferences at scale. A study by Accenture found that 91% of customers shop with brands that offer personalized experiences.

AI-Powered Predictive Analytics: Enhancing Decision-Making

Artificial Intelligence (AI) algorithms have revolutionized how businesses manage their operations, particularly in forecasting demand, optimizing routing, and enhancing decision-making. These algorithms utilize vast amounts of data, applying complex mathematical models to accurately predict future trends and behaviors. Here’s how AI works in these critical areas:

- Forecasting Demand

- Optimizing Routing

- Improving Decision-Making

Forecasting Demand

According to Forbes, AI algorithms analyze customer behavior, historical data on sales, market trends, weather patterns, and economic indicators. By recognizing patterns and correlations within this data, AI can predict future demand with high precision.

Optimizing Routing

In logistics, AI algorithms consider traffic conditions, delivery locations, vehicle capacities, and fuel efficiency to determine the most efficient delivery routes. These algorithms use real-time data and predictive analytics to minimize travel time and costs, improving overall operational efficiency.

Improving Decision-Making

AI supports decision-making by providing actionable insights derived from data analysis. For example, AI can suggest when to reorder stock in supply chain management, which suppliers offer the best terms, and how to allocate resources most effectively. This leads to reducing waste and maximizing profitability.

Benefits of Predictive Analytics

Here are the primary advantages of predictive analytics:

- Anticipating market trends

- Reducing Risks

- Enhancing supply chain resilience

Let’s discuss these in detail!

Anticipating Market Trends

Predictive analytics uses AI algorithms to identify and analyze patterns within large datasets, allowing businesses to anticipate market trends. By forecasting future consumer behavior and market conditions, companies can adjust their strategies proactively, staying ahead of competitors and meeting customer expectations.

Reducing Risks

AI-driven predictive analytics help businesses identify potential risks before they become critical issues. Companies can implement preventive measures by analyzing data on supply chain disruptions, financial fluctuations, and operational inefficiencies, reducing the likelihood of significant losses.

Enhancing Supply Chain Resilience

Supply chain resilience is crucial for maintaining uninterrupted operations. Predictive analytics enable companies to monitor and assess numerous factors impacting the supply chain, such as supplier performance, transportation delays, and geopolitical events. By predicting potential disruptions, businesses can develop contingency plans, ensuring they can adapt quickly and maintain continuity in their supply chains.

Transforming Inventory Management with AI

AI-enabled inventory management transforms how businesses track, forecast, and replenish their stock. Through real-time monitoring, advanced demand forecasting, and automated replenishment, AI delivers substantial efficiency gains, cost savings, and reduced stockouts. As a result, businesses can achieve agile and customer-centric supply chains, positioning themselves for sustained success in a competitive market.

AI Automates Inventory Tracking

A 2023 study published by Link Springer shows that AI transforms traditional inventory tracking methods by leveraging developed technologies such as IoT sensors, computer vision, and machine learning algorithms. These technologies enable real-time monitoring of inventory levels, locations, and conditions, ensuring that businesses always have an accurate view of their stock.

Real-Time Monitoring

AI-driven systems use IoT sensors to track real-time inventory movement and status. These sensors can detect when items are added or removed from storage, their location within a warehouse, and even environmental conditions like temperature and humidity that could affect perishable goods.

Computer Vision

Integrating AI with computer vision allows for automated scanning and recognition of products, reducing the need for manual inventory counts. Cameras equipped with AI can identify and count items on shelves, track their movement, and alert managers about discrepancies or low stock levels.

Demand Forecasting with AI

AI enhances demand forecasting by analyzing enormous amounts of data from numerous sources, including sales history, market trends, social media activity, and economic indicators. Studies highlight that machine learning algorithms can identify associations that human experts might miss, leading to more precise predictions.

Machine learning models analyze historical sales data and identify patterns to predict future demand. These models continuously learn and adapt, improving their accuracy over time. For example, a retail store can predict increased demand for specific products during holiday seasons or in response to promotional campaigns.

Replenishment Processes

AI optimizes replenishment processes by determining the ideal times and quantities for reordering stock, minimizing excess inventory, and reducing stockouts. In addition, AI-driven systems can automatically generate purchase orders based on real-time inventory data and demand forecasts.

Moreover, AI enables just-in-time (JIT) inventory management, where stock is replenished only as needed. This approach minimizes storage costs and reduces the risk of overstocking or obsolescence.

Cost Savings

By improving inventory levels and lowering the need for surplus stock, AI helps businesses save on storage and holding costs. Accurate demand forecasting minimizes the risk of stockouts and overstocking, further reducing operational expenses. Automated reordering processes also minimize administrative costs and improve procurement efficiency.

Reduced Stockouts

By accurately predicting demand and ensuring timely replenishment, AI helps maintain optimal stock levels, enhancing customer satisfaction and loyalty. Reduced stockouts also mean fewer lost sales opportunities and better overall business performance.

Streamlining Workflows through AI Integration

AI is revolutionizing logistics and supply chain management, offering companies new ways to streamline operations and reduce expenses. AI is transforming how businesses manage their logistics by automating routine tasks, enhancing accuracy, and providing comprehensive operational insights. Let’s examine a few real-world examples of successful AI implementation in logistics:

A German manufacturer partnered with Gramener, a global AI and data science firm, to create a data strategy aligned with their business goals. This collaboration led to impressive cost savings of approximately $30 million.

In a separate project, Gramener developed a digital twin of a pharmaceutical company’s drug production process. So this allowed the client to exert greater control over manufacturing and make on-the-fly adjustments based on data-driven insights. The result was $6 million in savings and improved production efficiency.

In the United States, a manufacturing company employed an AI solution for predictive maintenance of their truck fleet. By analyzing engine data over time, they could foresee potential issues before they occurred, avoiding costly repairs and minimizing unexpected downtime. The approach kept their trucks operating efficiently and economically while preventing delays caused by mechanical problems.

Enhancing Overall Efficiency in Logistics

Artificial Intelligence (AI) has revolutionized supply chain operations, transforming every stage from procurement to distribution. This holistic impact has increased efficiency, cost savings, and improved customer satisfaction across the entire supply chain ecosystem.

Procurement

In the procurement phase, AI has significantly enhanced supplier selection and management. Machine learning algorithms can analyze substantial data on supplier performance, market conditions, and risk factors to identify the most suitable partners.

AI-driven chatbots and virtual assistants streamline supplier communication, automating routine inquiries and negotiations. This not only saves time but also ensures consistent and accurate information exchange. Furthermore, AI helps detect potential supply chain disruptions early, allowing companies to mitigate risks and maintain business continuity proactively.

Production Planning

In production planning, AI optimizes resource allocation and scheduling. To create efficient production plans, advanced algorithms consider multiple variables such as demand forecasts, inventory levels, production capacity, and maintenance schedules. A report by McKinsey & Company revealed that AI-enabled production planning can increase overall equipment effectiveness by 10-15%.

AI also enhances quality control processes. Computer vision systems equipped with deep learning algorithms can detect product defects with greater accuracy and speed than human inspectors. This improves product quality and reduces waste, resulting in cost savings and increased customer satisfaction.

Warehouse Management

AI has transformed warehouse operations through intelligent automation. Robotics and AI work together to optimize picking routes, reducing the time and distance warehouse staff travel. According to a study by DHL, AI-powered warehouse management systems can improve productivity and accuracy.

AI algorithms also optimize inventory placement within warehouses, ensuring fast-moving items are easily accessible and storage space is utilized efficiently. Predictive analytics help anticipate demand fluctuations, allow for proactive inventory management, and reduce the risk of stockouts or overstocking.

Transportation and Logistics

AI is essential in route optimization and load planning in transportation and logistics. Machine learning algorithms analyze real-time weather conditions, traffic data, and historical patterns to find the most efficient delivery routes. A study by IBM found that AI-powered route optimization can decrease fuel costs by up to 25% and improve on-time deliveries by 30%.

Last-Mile Delivery

AI has significantly improved last-mile delivery, the supply chain’s most challenging and expensive part. Machine learning algorithms optimize delivery schedules and routes, considering traffic patterns, delivery time windows, and package characteristics. A report by Capgemini found that AI-driven last-mile optimization can reduce delivery costs by up to 40% and improve customer satisfaction by 30%.

AI-powered autonomous vehicles and drones are also being tested for last-mile delivery, promising to reduce costs and delivery times further. While still in the early stages, these technologies have the potential to revolutionize urban logistics and improve service in remote areas.

Customer Service and Returns Management

AI has transformed customer service in supply chain operations through intelligent chatbots and virtual assistants. These AI-powered tools can handle various customer inquiries, from order tracking to product information, providing instant responses and freeing human agents for more complex issues.

In returns management, AI algorithms analyze return patterns and reasons to identify potential quality issues or misleading product descriptions. This data-driven approach helps companies reduce return rates and improve customer satisfaction. AI also optimizes reverse logistics, determining the most cost-effective way to handle returned items: restocking, refurbishing, or recycling.

Challenges and Considerations

Data quality poses a hurdle in AI-driven supply chain optimization. Inconsistent data Inaccuracy can lead to flawed analyses. Organizations must implement rigorous data governance protocols to ensure the integrity of their information sources.

Cybersecurity threats loom as AI systems become more integrated into supply chain operations. AI algorithms or connected infrastructure vulnerabilities could expose sensitive business data or disrupt critical processes. Companies must fortify their digital defenses, employing encryption, access controls, and continuous monitoring to safeguard their AI-powered supply chains.

Human-AI collaboration presents both opportunities and challenges. While AI can augment human decision-making, resistance to change and fear of job displacement may hinder adoption. Organizations should focus on upskilling their workforce, fostering a culture of innovation, and communicating the benefits of AI integration to alleviate concerns and maximize synergies.

Here are the best practices for implementation of AI in the supply chain:

- Start with pilot projects: Begin with small-scale implementations to demonstrate value and gain organizational buy-in before scaling up.

- Prioritize data quality: Invest in robust data management systems and processes to ensure reliable inputs for AI algorithms.

- Foster cross-functional collaboration: Bring together supply chain, IT, and data science experts to develop holistic solutions.

- Implement change management strategies: Provide training and support to help employees adapt to new AI-driven processes.

- Establish ethical guidelines: Develop policies for responsible AI use, addressing bias and transparency.

Future Trends and Innovations

Autonomous supply chains represent a transformative vision for the industry. AI-powered systems could orchestrate end-to-end operations with minimal human intervention, from demand forecasting to inventory management and logistics optimization.

Edge computing integration will enable real-time decision-making at the point of action. By processing data locally on IoT devices, AI algorithms can respond to supply chain disruptions or opportunities with unprecedented speed and agility.

Moreover, Blockchain-AI convergence promises to enhance transparency and trust in supply networks. Smart contracts powered by AI could automate complex multi-party transactions, while blockchain’s immutable ledger ensures data integrity and traceability.

Quantum computing holds the potential to revolutionize supply chain optimization. As this technology matures, it could solve complex logistical problems at scales beyond the reach of classical computers, unlocking new efficiencies in routing, scheduling, and resource allocation.

Furthermore, predictive AI-powered maintenance will minimize downtime and extend asset lifespans. Machine learning models will analyze sensor data to anticipate equipment failures before they occur, enabling proactive maintenance and reducing supply chain disruptions.

Conclusion

AI is transforming supply chain management, offering powerful tools for optimization across all stages. From demand forecasting to logistics and inventory management, AI enhances efficiency and reduces costs. While challenges like data quality and cybersecurity exist, the benefits of AI integration are substantial.

Companies can have more innovative solutions as technology advances, including autonomous supply chains and quantum computing applications. By embracing AI responsibly and strategically, businesses can create agile, data-driven supply chains that adapt to market changes and meet customer needs effectively.